The function description and operation method of the MG series pulverizer

MG series plastic pulverizer is also called grinding disc pulverizer, Grinding disc pulverizer is mainly used to cut and grind materials among the gap between two grinding discs. Plastic pulverizer is named after years of practical use and operation, MG series Plastic Pulverizer (grinding disc type) of Jiangsu Lantai Machinery is designed and researched to meet the needs of customers based on the introduction of foreign advanced equipment. It is an ideal equipment for processing and grinding thermoplastic materials which are characterized by high softness, toughness and viscosity like PE, PP, soft PVC, and EVA ect, as well as plant fiber and leather materials. It is also a processing equipment for the recycling of plastic products. After the proof from the practice factory, the unit can maintain the target in the side of physics and chemical features when adding 20% to 30% grounding powder. The equipment has the advantages of high output, low energy consumption, adjustable of the size of grinding powder, convenient maintenance, environmental protection and pollution-free, and achieved a new level compared with similar products. Therefore, the equipment is a good helper for plastic products manufacturers to reduce costs and solve the problem of accumulation of waste products.

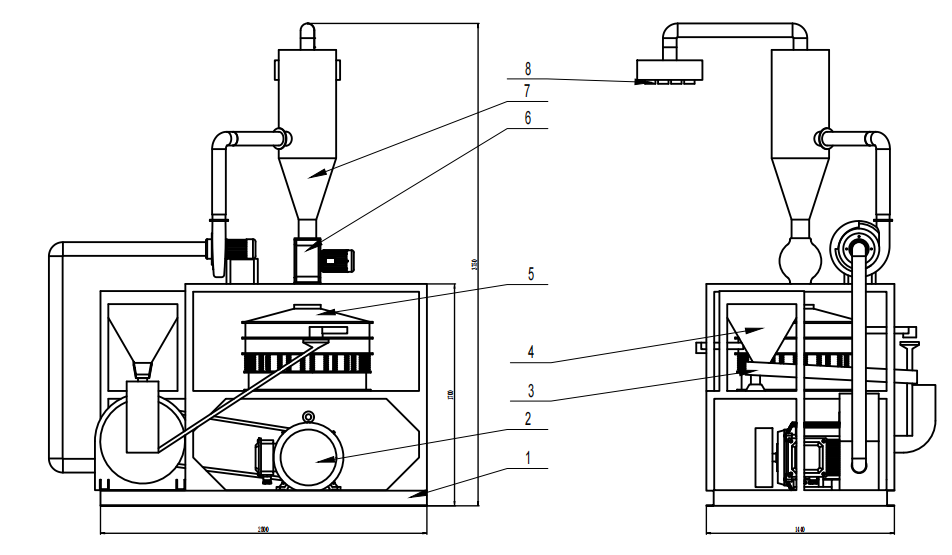

1. What is the role of each part of the MG series pulverizer?

(1) The function of the feeding machine is to send materials evenly to the grinding chamber.

(2) The plastic pulverizer mainly uses the high-speed rotation of the spindle cutter and the fixed cutter to collide and cut the incoming material with the cutter head.

(3) The function of suction fan is to transfer the grinded materials from the grinding chamber to the cyclone separator.

(4) The function of the cyclone separator is to separate the ground material from the air stream generated by the suction fan.

(5) The function of the off fan is to evenly send the ground material to the vibrating screen and isolate the wind in the cyclone separator.

(6) The vibrating screen is used to separate the grinded materials according to the requirements of their own mesh. The finished materials are packaged and the unqualified materials are returned to the grinding chamber for re-grinding through the pipeline.

(7) The function of the dust collector is to isolate the wind and a small amount of material from the cyclone separator.

2. Operation method of MG series pulverizer

(1) Before starting up, please carefully check whether the equipment connection is firm, whether the sealing is good, whether the line connection is correct, etc., and start-up after thorough check to make sure.

(2) Device booting steps: first turn on the main machine of the pulverizer, when the motor reaches the normal speed, then turn on the Suction fan, Off fan, Vibrating screen, and finally turn on the feeding machine. In the shutdown step, first, turn off the feeding machine, after 3-5 minutes, when there is no material in the grinding chamber, turn off the main machine of the pulverizer. After the main machine stops, turn off the suction fan, off fan and vibrating screen.

(3) Feed rate should based on the host load size: if the main machine load is too large, please reduce the feed, If the load is not enough, increase the feeding quantity to ensure the normal operation of the main machine under the rated load.

(4) When processing heat-sensitive materials, the load of the main motor should be adjusted to slightly lower than the rated power value.

(5) The tension bridle degrees of the V-belt should be checked regularly to prevent the belt from slipping and the belt tension should be 2-2.7kgf.

(6) According to different materials and different sizes of powder, grinding disc pulverizer needs to control the mesh by adjusting the interval in the grinding disc.

The above is part of my introduction to the function description and operation method of MG series Pulverizer. If you have any questions or want to know more about plastic machinery, please contact me. My name is Luna, my email address is luna@lantaimachinery.com, WhatsApp/Wechat: + 86-13519648306.