Introduction of single-screw extruder

In the last month, I found that many customers asked about the extruder. Today I will briefly introduce our single-screw extruder. I hope this article can be helpful to everyone.

1. Introduction of single-screw extruder

As the name implies, the extruder is an extrusion molding process, which is the molding process for the production of plastic products with the same cross-sectional shape and any length (eg: pipes, rods, plates and various profiles, etc.). It has the following three characteristics:

(1) The extrusion production process is continuous;

(2) High production efficiency and wide application range;

(3) Less investment and quick results.

2. Plastic extrusion process

Extrusion molding refers to adding powder or granular materials from the hopper to the barrel of the extruder. The materials are conveyed and compacted by the friction between the inner wall of the barrel and the surface of the screw under the pushing action of the rotation of the screw. Through the heating device and friction preheating outside the barrel, it is melted and plasticized under high temperature and high pressure, and then the continuously rotating screw conveys the molten material into the die. The molten material extruded from the die is cooled and shaped into the final required plastic products.

3. Mechanical structure of single-screw extruder

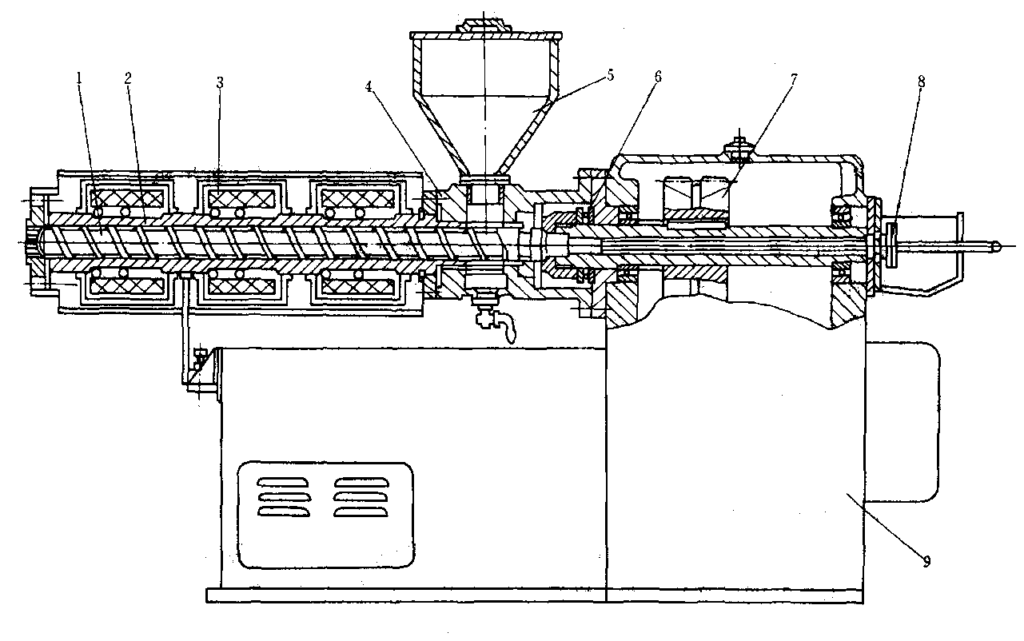

The main machine of the extruder is mainly composed of an extrusion system, a transmission system, heating and cooling system, and a body of machine. As shown below:

- Screw 2-Barrel 3-Heater 4-Hopper support 5-Hopper 6-Thrust bearings

- Transmission system 8-Cooling system 9-Body of machine

4. Technical parameters

(1) Screw diameter Db (series: 20, 30, 45, 65, 90, 120, 150, 165, 200, 250, 300, etc.);

(2) L/Db of screw;

(3) Rotational speed range of screw;

(4) Motor power of main screw;

(5) Production capacity of the machine;

(6) Main parameters of the screw (section, groove depth, compression ratio, pitch, thread rise angle, thread number, thread edge width, thread groove width, etc.);

(7) Number of heating sections, etc.

5. Control parameters of the extrusion molding process

It mainly depends on several parameters, such as temperature, pressure, extrusion rate (or extrusion volume, output capacity) and energy (or power).

6. Extruder parts

(1) Main parts include screw and barrel;

(2) Other parts include transmission system, heating and cooling device, feeding device, splitter plate and filter screen.

Finally, if this article still doesn’t solve your questions, you will tell me and we will discuss it together. This is my contact information: +86-173 6162 1611, my name is Amy.