About the double-stage pelletizing line for film

Recently, there are a lot of people ask me some questions about the pelletizing line for film. So I write this paper to help you know about the pelletizing line for film. But it is a brief and summary. Please contact me if you have any questions about this line, thank you very much!

I. Application and features:

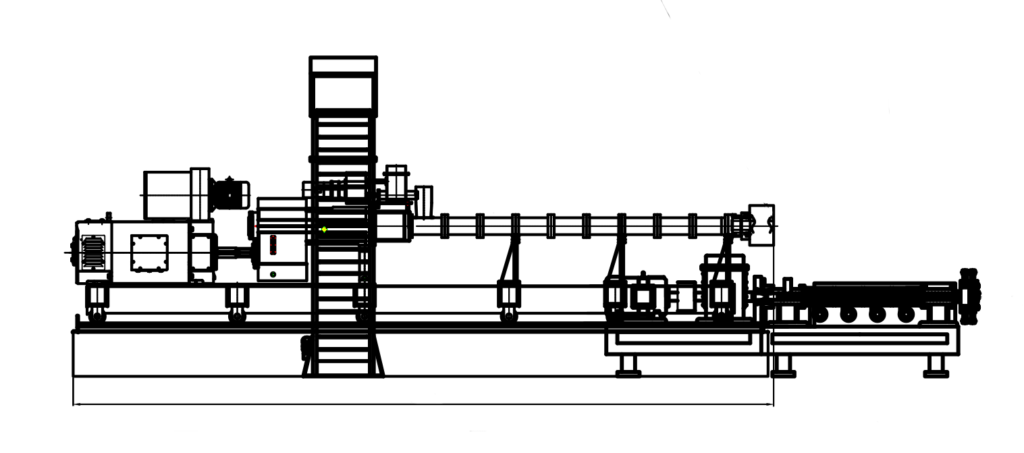

This double-stage pelletizing line consists of belt conveyor, compactor, extruder, die head, hydraulic screen changer, cooling tank, pelletizer, etc. This pelletizing line is an ideal equipment to recycle and pellet plastic film, filiform plastic, waste plastic bags. It has many features, such as construction, reasonable layout, low noise and low consumption. Also, it runs smooth, and it is convenient to adjust and maintain.

Requirements for environment:

Location: indoor

Electricity safety zone

0.85 no condensation point

Temperature: 0-40℃

Belt conveyor

This belt conveyor adopts PVC, because it is wear-resisting and anti-corrosion, and it can not pollute material conveyed. This belt can be adjusted to extend its service life. And it has low noise. This belt conveyor is equipped with wheels to convenient for moving. It can work in any environment.

Method of application:

Please check if the belt conveyor is smooth before start it.

Please notice if the rotary direction of main shaft is correct, and listen to machine carefully if there is unusual noise. Then please let the machine run 3-5 minutes. If everything is normal, please feed material.

Attention points:

You should add 3# or 4# calcium-based grease lubricating oil for every bearing weekly. And check every bearing if runs normally. And you should add industrial gear oil for reducer monthly, and add lubricating oil L-AN100 for chains weekly.

The belt should be cleaned when the machine stops to work.

Please adjust the belt after it is used for a while. Please confirm that the belt runs in the middle of the whole machine.

Please keep the machine in good contact with the ground in case the motor leak current.

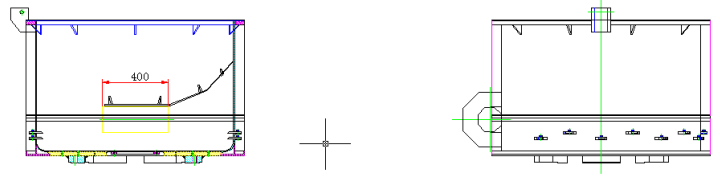

II. Compactor:

It is used to crush and agglomerate film.

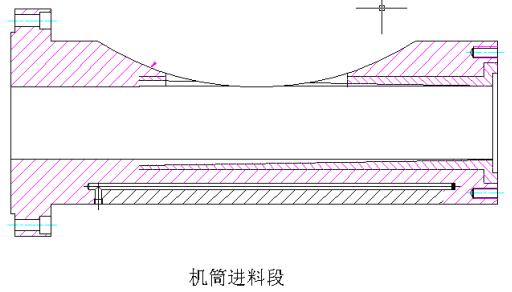

III. Single-screw extruder:

This extruder adopts parallel triaxial design, and it has reasonable layout. The box adopts high quality cast iron.

IV. single-screw extruder:

Vacuum system:

There are vents on the barrel to exhaust water vapor to improve the quality of pellets.

Hydraulic screen changer:

It consists of hydraulic station, plate and heating device.

Hydraulic station consists of motor, oil pump, accumulator, pressure relay, reversing valve, pressure regulating valve, etc..

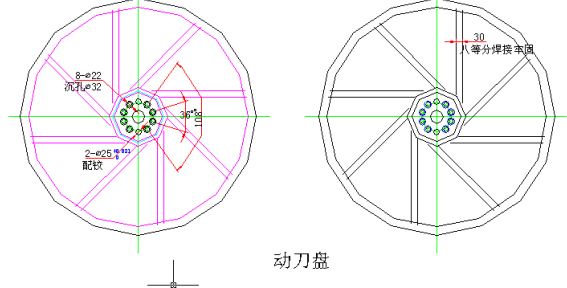

V. Pelletizer

Method of application:

Please check all motors if rotate correctly. And the machine should run 3-5 minutes without material.

This machine can be used alone, and it also can be used with other machines.

Attention points:

You should add 3# or 4# calcium-based grease lubricating oil for every bearing weekly. And check every bearing if runs normally. And you should add industrial gear oil VG 220 for reducer monthly.

Because this machine has high rotary speed, so please do not put big size into machine.

Please adjust belt and screws when it is used for a while.

Thanks for your time to read this paper, please let me know if you have any questions and advice about this article. Thank you very much!