Similarities and differences between LTBC-belt conveyor and LTSL-screw loader

Because my colleague introduced what belt conveyor and LTSL-LTSL-screw loader are. I write down this article to help more people know about similarities and differences between belt conveyor and screw conveyor clearly. And this article also help more people to choose the better machine.

1. Similarities between LTBC-belt conveyor and LTSL-LTSL-screw loader

1.1 Similar structure

Both LTBC-belt conveyor and LTSL-LTSL-screw loader are driven by main motor, and material is conveyed to the destination by transmission system.

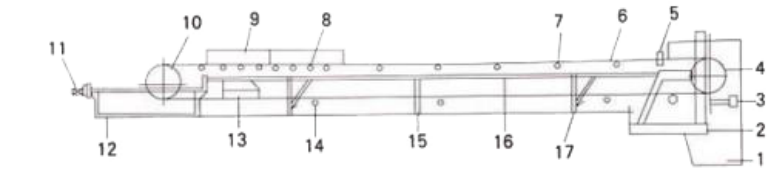

The name of spare part

1.Head hopper 2. Rack 3. Washer

4.Transmission drum 5. Safety production device 6. Belt conveyor

7.Carrying idler 8. Buffer roller 9. Feed channel

10.Bend pulley 11. Screw take-up device 12. Tail stock

13.Nonloaded cleanser 14. Return roller 15. I-shaped outrigger

16.The middle frame 17. II-shaped outrigger

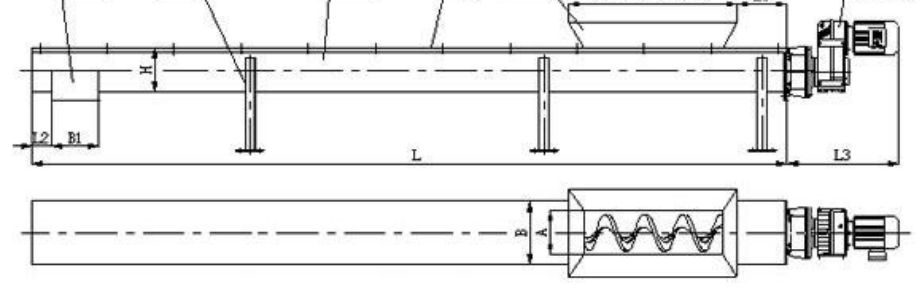

Discharge port rack U-shaped tank Cover plate Feeding port(produced according to customers’ requirements) Drive device

1.2 Similar function

Both LTBC-belt conveyor and LTSL-LTSL-screw loader are designed for conveying material. They are mainly used to convey material form one side to another side to reduce labor costs.

1.3 Similar price

Although both LTBC-belt conveyor and LTSL-LTSL-screw loader have similar structure, but there are differences between LTBC-belt conveyor and LTSL-LTSL-screw loader in main structure. So their production costs are different sometime. But their price will almost same when they have the same conveying capacity. For example, when both LTBC-belt conveyor and LTSL-LTSL-screw loader are chosen to convey 200kg material, the price difference between LTBC-belt conveyor and LTSL-LTSL-screw loader is about 2000RMB. But this price difference is changeable. Price difference between LTBC-belt conveyor and LTSL-LTSL-screw loader depends on different molds. Please contact me if you want to know about specific prices of LTBC-belt conveyor and LTSL-LTSL-screw loader.

2. Differences between belt conveyor and LTSL-LTSL-screw loader

2.1 Differences in main structure

Although I mentioned that structure between belt and LTSL-LTSL-screw loader are similar generally, there are many differences between LTBC-belt conveyorand LTSL-LTSL-screw loader. So LTBC-belt conveyor and LTSL-LTSL-screw loader are totally different because of these differences.

2.2 Differences in transmission device

The LTBC-belt conveyor mainly consists of rack, belt, belt roller, tensioning device, transmission device, etc. Belt conveyor is supported by upper and lower rollers. The belt conveyor is a conveying machine whose roller forms a closed loop. The belt conveyor uses friction between drive roller and belt to transmission power to convey material. And the direction of conveying can be adjusted. LTSL-LTSL-screw loader takes advantage of motor to drive main shaft to rotate. And the main shaft drives blades of screw to drive and push material forward. When material is fed into LTSL-LTSL-screw loader, the material and blades of screw will rotate because of centrifugal force and friction. Because of action of gravity, material will slip along screw groove, so the material will be pushed forward to convey. Finally, the material will be discharged from discharge port. But some LTSL-LTSL-screw loaders do not have main shaft, so they are called shaftless LTSL-LTSL-screw loader. Its structure is a little different for LTSL-LTSL-screw loader with shaft. We will introduce it next time. The LTSL-LTSL-screw loader I mentioned is LTSL-LTSL-screw loader with shaft.

2.3 Differences in material conveyed

LTBC-belt conveyor and LTSL-LTSL-screw loader convey different material because their structure is different. The structure of LTBC-belt conveyor is simple, and material is placed on belt to convey. So belt conveyor mainly convey big or block material. It does not apply to convey powder, etc. Because it will generate many problems when you place powder material on belt. About that, there is an example: I have a customer who comes form Saudi Arabia, he bought our belt conveyor, but there is something happened when he uses our machine to convey material. Because he described wrong material for me at the beginning. He told that he uses belt conveyor to convey block material. But I found that he conveyed powder material when I saw the video he sent to me. Because it does not design the special structure to stop powder material into belt conveyor, so it will lead to part of powder enter the internal of belt conveyor. And powder material will block the roller. So belt conveyor does not apply to such powder material. But LTSL-LTSL-screw loader mainly apply to convey powder material. Because it conveys material from inside. It can effectively prevent waste. Because it can achieve the effect of sealed conveying. From above cases, we find that we have different plans to deal with different cases to reach all of requirements. There are many kinds of material, so I can not introduce them one by one here. In a one word, we should choose different conveyor to convey different material.

2.4 Differences in output capacity

Because LTSL-LTSL-screw loader has various type, such as LTSL-LTSL-screw loader with shaft, shaftless LTSL-LTSL-screw loader, U-type LTSL-LTSL-screw loader and pipe-shaped LTSL-LTSL-screw loader, so they have different conveying capacity. Generally, the conveying capacity of LTSL-LTSL-screw loader is 1.4-458m³/h, and the conveying length is 40-60m. But the conveying capacity of LTBC-belt conveyorcan reach to 30-3000t/h, and the conveying length can reach 180m, and it has extremely efficient.

All of these are similarities and differences between LTBC-belt conveyor and LTSL-LTSL-screw loader. Please contact me if you have any problems when you choose to conveyor. At the same time, I hope this article can help you.